What is Finger Nail Polish Made Of?

Base Ingredients of Nail Polish: What Is Finger Nail Polish Made Of

What is finger nail polish made of – Nail polish, a seemingly simple cosmetic, boasts a surprisingly complex composition. Its formulation involves a careful balance of several key ingredients to achieve the desired color, shine, durability, and application properties. Understanding these base components is crucial to appreciating the science behind this ubiquitous product.

Film-Forming Polymers

Film-forming polymers are the backbone of nail polish, providing the structural integrity of the dried film. These polymers, typically nitrocellulose, create a flexible yet durable layer on the nail. The choice of polymer significantly impacts the nail polish’s texture, shine, and overall performance. Other polymers, such as acrylic resins and vinyl polymers, may be included to modify properties such as flexibility, adhesion, and gloss.

Resin Types and Properties

Various resins are employed in nail polish formulations, each contributing unique characteristics. For instance, rosin, a natural resin, adds tack and contributes to the film’s adhesion. Synthetic resins, such as acrylic resins, offer greater control over film properties, allowing for customization of flexibility, hardness, and gloss. The selection of resins is critical in determining the final nail polish characteristics.

Percentage Composition of Nail Polish Base

A typical nail polish base comprises approximately 30-40% film-forming polymers, with the remainder consisting of solvents, plasticizers, and other additives. The exact proportions vary depending on the desired properties and the specific formulation.

Common Base Ingredients

| Ingredient | Chemical Name | Function |

|---|---|---|

| Nitrocellulose | C6H7N3O9 | Primary film-forming polymer, provides strength and flexibility |

| Rosin | (Variable, complex mixture of resin acids) | Natural resin, improves adhesion and tack |

| Acrylic Resin | (Variable, depending on specific type) | Synthetic resin, modifies film properties (flexibility, hardness, gloss) |

| Butyl Acetate | C6H12O2 | Solvent, aids in application and drying |

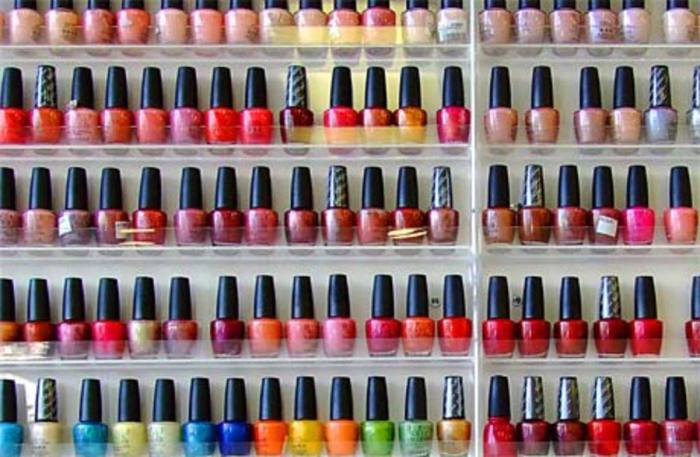

Pigments and Colors

The vibrant colors of nail polish are achieved through the incorporation of pigments, finely ground particles that absorb and reflect light at specific wavelengths. The type and concentration of pigment determine the final shade and opacity of the nail polish.

Nail polish typically contains film-forming polymers, solvents to help it flow, and pigments for color. The specific ingredients can vary, but for a luxurious experience, consider checking out the services offered at sugar polish nail bar athens , where they likely use high-quality formulations. Understanding the composition of nail polish helps in choosing products that suit your nail health and desired finish.

Types of Pigments and Their Properties, What is finger nail polish made of

A wide array of pigments is used, including organic and inorganic varieties. Organic pigments, often derived from synthetic sources, provide bright and intense colors, while inorganic pigments, such as iron oxides, offer a range of earthy tones and often enhanced durability. Pearlescent pigments, composed of mica coated with metal oxides, create a shimmering effect, while metallic pigments provide a reflective, metallic finish.

The selection of pigments is a crucial aspect of nail polish formulation, affecting not only the color but also the lightfastness and overall durability.

Challenges in Achieving Consistent Color

Maintaining consistent color across different batches of nail polish presents significant challenges. Variations in pigment particle size, distribution, and the manufacturing process can all lead to inconsistencies in color. Rigorous quality control measures are essential to ensure uniformity.

Lightfastness and Durability of Pigments

The lightfastness and durability of pigments vary considerably. Some pigments are more resistant to fading from sunlight and wear than others. This factor influences the longevity and appearance of the nail polish over time. Formulators carefully select pigments based on the desired colorfastness and durability.

Comparison of Natural and Synthetic Pigments

| Type | Source | Properties | Examples |

|---|---|---|---|

| Natural | Mineral or plant sources | Often less vibrant, may have lower lightfastness | Iron oxides, carmine |

| Synthetic | Chemically synthesized | Wide range of colors, potentially higher lightfastness | Phthalocyanines, azo pigments |

Solvents and Additives

Solvents and additives play a crucial role in the formulation of nail polish, impacting its application, drying time, and overall performance. These components contribute to the desired texture, consistency, and longevity of the product.

Common Solvents and Their Purpose

Solvents are volatile liquids that dissolve the other ingredients, creating a smooth, paintable consistency. Common solvents include ethyl acetate, butyl acetate, and ethanol. These solvents evaporate during the drying process, leaving behind the film-forming polymers and pigments.

Plasticizers and Adhesion Promoters

Plasticizers, such as dibutyl phthalate, enhance the flexibility of the dried nail polish film, preventing cracking and chipping. Adhesion promoters improve the bonding between the nail polish and the nail surface, ensuring a long-lasting manicure.

Impact of Solvents on Drying Time and Finish

The choice of solvent significantly impacts the drying time and finish of the nail polish. Faster-evaporating solvents lead to quicker drying times, but may also result in a less smooth finish. Slower-evaporating solvents allow for better leveling and a smoother appearance, but extend the drying time.

Common Additives and Their Impact on Nail Health

- Formaldehyde: Hardener, potential irritant and allergen.

- Toluene: Solvent, potential irritant and neurotoxin.

- Dibutyl phthalate (DBP): Plasticizer, potential endocrine disruptor.

- Camphor: Plasticizer, potential irritant.

Manufacturing Process

The production of nail polish involves a series of carefully controlled steps, from mixing and milling to quality control and packaging. Each stage is critical in ensuring the final product meets the desired quality and safety standards.

Mixing and Milling

The manufacturing process begins with the precise mixing of the various ingredients, including polymers, pigments, solvents, and additives. This mixture is then milled to ensure a uniform dispersion of pigments and a smooth, consistent texture. The milling process reduces pigment particle size and prevents clumping, which is essential for a smooth application and even color.

Quality Control Measures

Rigorous quality control measures are implemented throughout the manufacturing process to ensure consistency and safety. This includes testing for viscosity, color, and the presence of any harmful contaminants. The finished product is also subjected to various performance tests, such as chip resistance and drying time.

Packaging and Labeling

Once the nail polish has passed quality control, it is packaged into appropriate containers and labeled according to regulatory requirements. This includes specifying the ingredients, safety precautions, and any warnings.

Flowchart of the Manufacturing Process

The manufacturing process can be represented as a flowchart: Ingredient Preparation -> Mixing -> Milling -> Quality Control -> Filling -> Packaging -> Labeling -> Distribution.

Health and Safety Considerations

Source: hubstatic.com

While nail polish enhances beauty, certain ingredients pose potential health risks. Understanding these risks and adhering to safety guidelines is crucial for minimizing potential harm.

Potential Health Risks of Nail Polish Ingredients

Source: stylish-nails.com

Some nail polish ingredients, such as formaldehyde, toluene, and DBP, have been linked to various health issues, including skin irritation, allergic reactions, and potential long-term health effects. The concentration of these ingredients and the duration of exposure are significant factors determining the risk.

Regulations and Safety Standards

Regulations governing the composition and labeling of nail polish vary across different regions. Many countries have banned or restricted the use of certain harmful ingredients, such as formaldehyde and DBP, in nail polish formulations. Manufacturers must adhere to these regulations to ensure the safety of their products.

Impact of Prolonged Exposure

Prolonged exposure to nail polish chemicals, through repeated application and inadequate ventilation, can increase the risk of health problems. Good ventilation and proper handling practices are essential to minimize exposure.

Safe Handling and Disposal

Nail polish should be handled in a well-ventilated area, and direct skin contact should be minimized. Used nail polish and containers should be disposed of properly, according to local regulations.

Common Hazardous Ingredients and Their Health Effects

| Ingredient | Potential Health Effects |

|---|---|

| Formaldehyde | Skin irritation, allergic reactions, respiratory problems |

| Toluene | Headaches, dizziness, nausea, developmental effects |

| Dibutyl phthalate (DBP) | Endocrine disruption, reproductive effects |

| Camphor | Skin irritation, respiratory problems |

Different Types of Nail Polish

The market offers a variety of nail polish types, each with unique properties and application methods. These differences stem from variations in chemical composition and the curing process.

Comparison of Nail Polish Types

Regular nail polish, gel polish, and shellac each differ significantly in their composition, application, and durability. Regular nail polish relies on solvent evaporation for drying, while gel and shellac require UV or LED curing. This affects their longevity and removal processes.

Chemical Differences and Durability

Gel polish typically contains oligomers and monomers that polymerize under UV or LED light, creating a hard, durable coating. Shellac is a hybrid, combining properties of both regular and gel polish. The chemical differences account for the varying application techniques and removal processes.

Removal Processes

Regular nail polish is easily removed with nail polish remover. Gel and shellac require soaking in acetone to break down the polymerized structure.

Chemical Composition Comparison

| Type | Key Components | Curing Method | Removal Method |

|---|---|---|---|

| Regular | Nitrocellulose, plasticizers, pigments, solvents | Solvent evaporation | Acetone |

| Gel | Oligomers, monomers, photoinitiators, pigments | UV/LED curing | Acetone soaking |

| Shellac | Hybrid of regular and gel components | UV/LED curing | Acetone soaking |

Visual Representation of Nail Polish Components

Microscopic Structure of Dried Nail Polish Film

Source: passionforsavings.com

At a microscopic level, a dried nail polish film exhibits a complex network of interconnected polymer chains. These chains are intertwined, forming a continuous matrix that encapsulates the pigment particles. The arrangement of the polymers and pigments influences the film’s overall properties, such as flexibility, hardness, and gloss. The pigments are dispersed throughout the polymer matrix, contributing to the overall color and opacity of the film.

The degree of polymer entanglement and pigment dispersion impacts the film’s strength and durability.

Interaction Between Nail Polish Components and Nail Surface

At a molecular level, the interaction between the nail polish and the nail surface involves adhesion forces. The components of the nail polish, particularly the adhesion promoters and resins, interact with the keratin proteins of the nail, creating a bond that holds the polish to the nail. The strength of this bond depends on the chemical nature of the adhesion promoters and the surface properties of the nail.

This interaction is crucial for the longevity and durability of the manicure.

FAQ Explained

Can nail polish cause allergic reactions?

Yes, some ingredients in nail polish, such as formaldehyde or toluene, can cause allergic contact dermatitis in sensitive individuals.

How long does nail polish typically last?

The longevity of nail polish depends on the type (regular, gel, shellac), application technique, and individual wear patterns. Regular polish typically lasts a few days, while gel and shellac can last for several weeks.

Is it safe to use nail polish remover frequently?

Frequent use of nail polish remover, especially those containing acetone, can dry out and damage nails. Using a gentler remover and applying cuticle oil can help mitigate this effect.

Are there vegan and cruelty-free nail polish options?

Yes, many brands now offer vegan and cruelty-free nail polishes that are free from animal-derived ingredients and are not tested on animals.